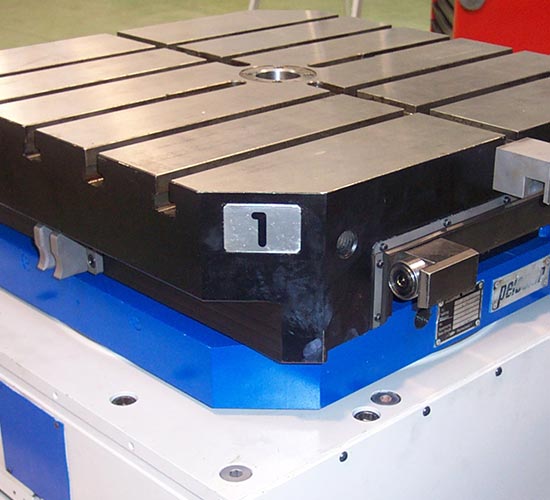

360° assistance

Technical assistance: what we do

We are able to give quick feedback both through phone helpline and technical interventions on-site. We also provide preventive and corrective maintenance activities complying with a planning agreed on the basis of our clients production timeline and closing periods. Maintenance activities are essential for the machine to work properly, reducing brakedowns and extending its life time.

Among our services:

Among our services:

- Full technical assistance (electrical, mechanical, systems)

- diagnostic activities ( one/two days) to identify issues during operation

- Geometric, laser interferometric, ball-bar testing

- CNC retrofitting (Siemens, Fanuc, Heidenhain, Fagor, D-Electron, Num)

- Software design for industrial automation

- Programming and turnkey projects

- Operators training for the proper use of the machine functionality

- Standardisation and CE certification

- Machining centers replacement

- Certified reports